Products

1) Pickling Additive Galvacid® 2C

GALVACID® 2C is used as an additive

in the pickling bath, its formulation includes the pickling potential of

inorganic acids and salts and compatible organic compounds, aimed at modifying

the surface tension, the vapor pressure of CLH ↑, and controlling the attack on

metal, as well as increasing the longevity of the pickling bath.

The working solutions prepared

with GALVACID®-CLASS 2C and HCL, project higher pickling speeds than those

obtained with pure inorganic acids, significantly minimizing the evolution of

hydrogen chloride fumes, radically improving environmental conditions and,

therefore, the consequent reduction in the rate of corrosion in equipment and

structures. Also, pickling is obtained with a higher degree of surface

cleaning, which is noticeable with the naked eye.

It is commonly supplied in IBCs of 1000 L.

Download Paper AGA BALTIMORE 1999 - "NOVEL PICKLING ACID for the METAL FINISHING INDUSTRY"

Additional documentation such as SDS and References are provided upon request

2) Eco Friendly Ammonium Free Flux Ammonium Free Galvanizing Flux Galvacid® Flux HSC (High Surface Conversion)

GALVACID® FLUX HSC is a concentrated solution of Pre-Flux, for high surface conversion, free of ammonium chlorides, not typical of conventional fluxes, with high surface conversion, free of chlorides of ammonium, not typical of conventional fluxes, which usually contain between 45% and 55% Ammonium Chloride. These properties contribute to an absolute improvement in the work environment, by totally eliminating toxic ammonia NH3↑ gases derived from the use of these traditional fluxes with high ammonium chloride (NH4Cl) contents, which in turn are precursors for the formation of N2O in the atmosphere, one of the main gases that cause warming on the planet, with a warming potential 298 times greater than CO2 and which also affects the health of personnel and corrodes the structures of buildings and stored raw materials. It is commonly supplied in IBCs of 1000 L.

Additional documentation such as SDS and References are provided upon request

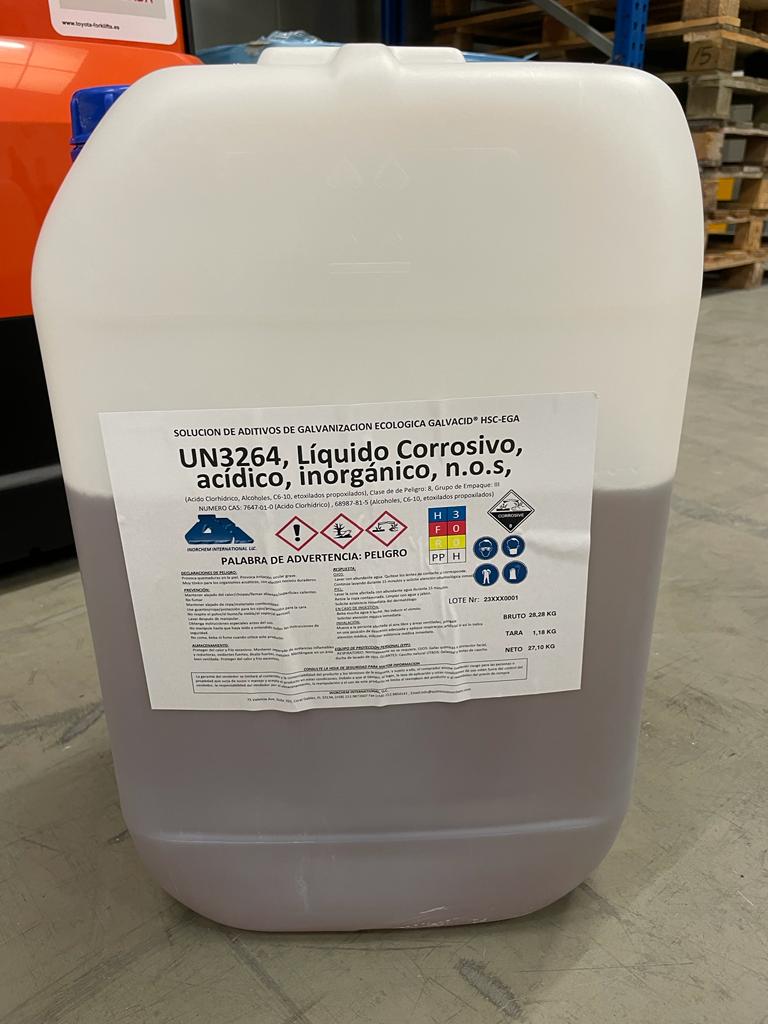

3) Eco Friendly Ammonium Free Aditive for Galvanizing Fluxes

Ammonium Free Galvanizing Flux Galvacid® Flux EGA (High Surface Conversion)

The solution of ecological galvanizing additives GALVACID® HSC-EGA is a concentrated solution that is added to Zinc Chloride in 62.5% solution, to obtain the galvanizing Flux (Pre-Flux), for high surface conversion, free of ammonium chlorides, not typical of conventional fluxes, which usually contain between 45% and 55% Ammonium Chloride. These properties contribute to an absolute improvement in the work environment, by totally eliminating toxic ammonia NH3↑ gases derived from the use of these traditional fluxes with high ammonium chloride (NH4Cl) contents, which in turn are precursors for the formation of N2O in the atmosphere, one of the main gases that cause warming on the planet, with a warming potential 298 times greater than CO2 and which also affects the health of personnel and corrodes the structures of buildings and stored raw materials. It is commonly supplied in IBCs in 20 L Jerrycans.